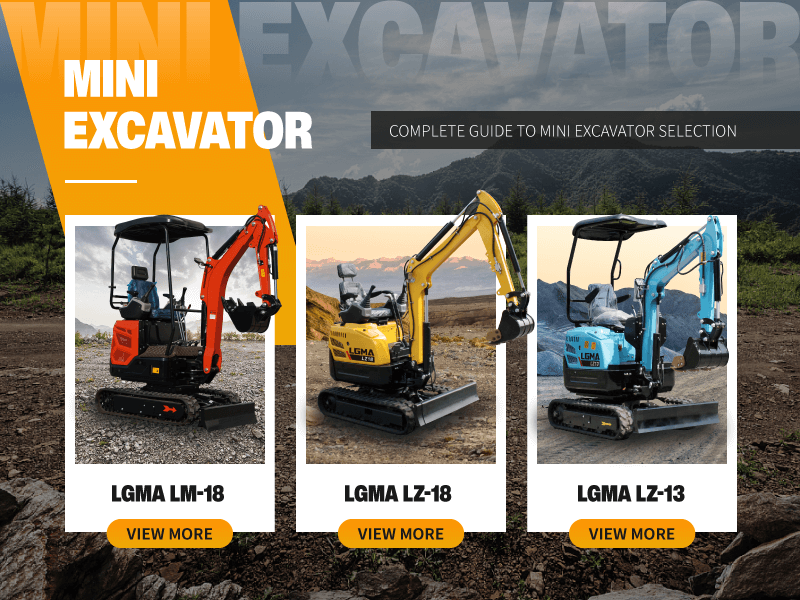

Mini Excavator Buying Guide: A Decision-Making Guide from Tonnage to Configuration

In today’s infrastructure and landscaping markets, mini excavator has become a popular investment choice due to their high flexibility and low entry costs. This article combines the technical advantages of the LGMA LZ series mini excavators to provide you with a scientific selection decision-making plan, helping you precisely match your operational needs.

Selecting Tonnage Based on Work Scenarios

The operating weight of a excavator directly determines its working range and transport convenience. Below are recommended options for different needs:

| Tonnage Class | Representative Models |

Operating Weight |

Core Advantages |

Suitable Scenarios |

| Under 1 ton | LZ08 / LZ12 | 750-950kg | Ultra-lightweight, exceptional maneuverability in confined spaces | Indoor demolition, private gardens, narrow alleys |

| 1-2 Ton Class | LZ15 / LZ17-2 | 1100-2000kg | Balances digging force and maneuverability |

Rural roads, farmland irrigation, livestock farms |

| 3-6 Ton Class | LG60 | Highest overall economy, fast operation efficiency | Suitable for engineering contracting and large-scale farm operations |

Key Specifications for Mini Excavators

When comparing specifications, focus on the following five dimensions:

- Power System and Environmental Standards

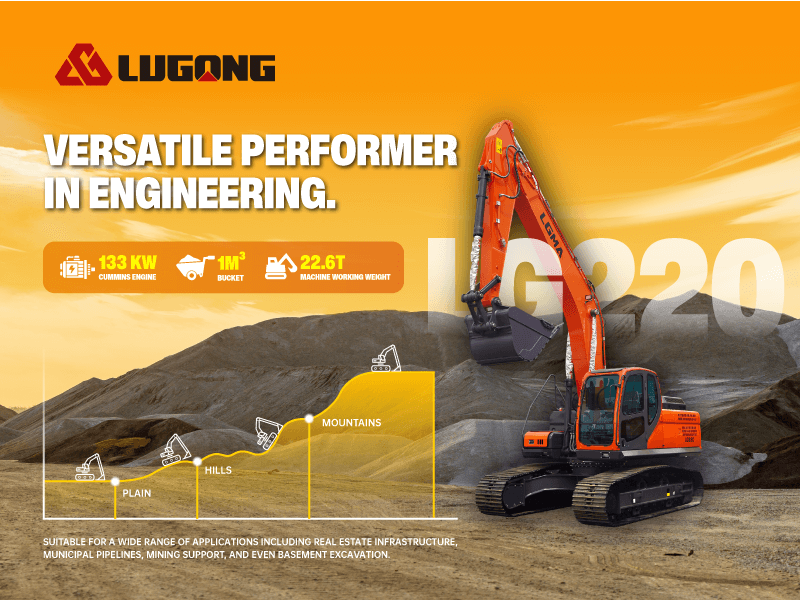

The engine is the heart of an excavator. To meet global market demands, Lugong mini excavators are certified to Euro V/EPA Tier 4 standards.

Efficient Power: The Lugong LZ20/LZ25 offers optional Yanmar 3TNV80 or Changchai/Laidong 30HP engines.

Emission Standards: Ensure compliance with local environmental regulations.

- Hydraulic System Sophistication

Premium mini excavators should feature load-sensing hydraulic systems:

Hydraulic System: Prioritize models with load-sensing hydraulics, which intelligently allocate flow based on load demands. This enables coordinated compound movements, rapid response, and energy efficiency.

Hydraulic Pilot Control: Compared to mechanical levers, pilot control offers greater precision and reduced operator effort, significantly boosting productivity.

- Undercarriage and Structural Strength

Undercarriage Design: Opt for box-type undercarriage structures with superior torsional rigidity. This significantly enhances overall machine stiffness and resistance to deformation.

Durable Components: Verify the inclusion of a reinforced, widened dozer blade and an all-steel body. These features ensure long-term reliability under harsh operating conditions.

- Safety and Comfort

Safety: The hydraulic pilot safety lock on the LZ20/25 effectively prevents accidental operation risks.

Comfort: Features like an open-view cab, adjustable armrest box, and even air conditioning/radio configuration are standard in modern construction machinery to reduce operator fatigue.

- Multi-Functional Expandability

Quick-change attachments are the core competitive advantage of mini excavators. By switching attachments, a single machine can perform multiple tasks:

Hydraulic Breaker: Demolition projects.

Auger: Building foundations.

Grapple: Landscaping and agriculture.

Summary:

For small-scale contractors, the 3-5 ton LZ20 offers the best value. For urban interior renovations, the sub-1 ton LZ08 is the top choice. For more information on mini excavators, contact Lugong Mini Excavator Manufacturer.